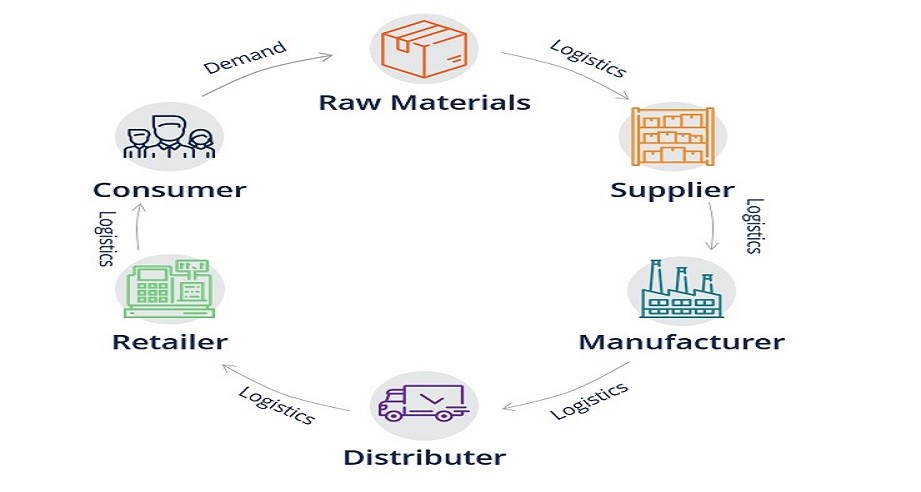

If there’s one thing this pandemic has taught us, it’s that our suppliers are utterly essential to what we do.

As we move forward, we need to be aware of how our industry has been affected and the ways we need to change how we work with suppliers to avoid these issues again. These changes in how we function in relationship with our suppliers fit into three buckets:

· Having strong contractual agreements with existing suppliers

· Having alternative suppliers for critical categories

· Cultivating relationships with suppliers

While these buckets apply to procurement as a whole, they are especially sensitive in the biotech space because the timelines are so critical. Time is of the essence, no matter where a product is in the development cycle. Whether in the research phase or early-or late-stage clinical development, it’s a race against time. As FDA submission and PDUFA timelines approach, organizational agility and supply reliability become increasingly important. COVID-19 has revealed how often agility and reliability are missing.

Strong Contractual Agreements With Existing Suppliers

Revising contracts to ensure the right force majeure language is included ensuring continuity of supply is incredibly important. Recognition that we need the right KPIs and contracts has been catapulted as a result of this global pandemic. Knowing what, where and how a good or service must be delivered is imperative to have clearly defined in a supplier contract.

Alternative Suppliers for Critical Categories

It’s great to have a global supply chain, but we’ve realized the importance of having a network of alternatives that are closer to home. At the end of January 2020, manufacturing in China shut down for three weeks. And once it started up again, it was slow going because of new regulations and trying to play catch up. Things we can’t even fathom happen, and we need to be prepared to quickly switch suppliers when necessary.

Cultivating Relationships With Suppliers

Supplier relationships can’t just be tactical. Cultivating partner relationships with suppliers ensures both sides know they can rely on each in challenging times. While cost savings and cost avoidance are important considerations, lengthening payment terms to suppliers right now is not the right thing to do. They are an extension of your company. And there’s a time and a place for putting cost at the forefront – make sure to do marketplace checks. A global pandemic is not the time to squeeze suppliers. The reliability of supply is critical. And if you need to pay them faster, pay them faster so that you cultivate that relationship and know that they’re going to be there when you need them.

Developing stronger relationships with suppliers helps everyone. Recognizing where we need to revise contract language, building a collection of alternative suppliers in near shore regions, and reconsidering how to interact with suppliers collaboratively, even if it occasionally increases cost, can help weather the next unexpected supplier crisis together.